From the outside, the photobooth process appears simple; customers sit down, pay with a card and pose as the camera flashes. After four minutes the photo strip is deposited in a delivery unit on the outside of the booth and the happy customer goes on their way.

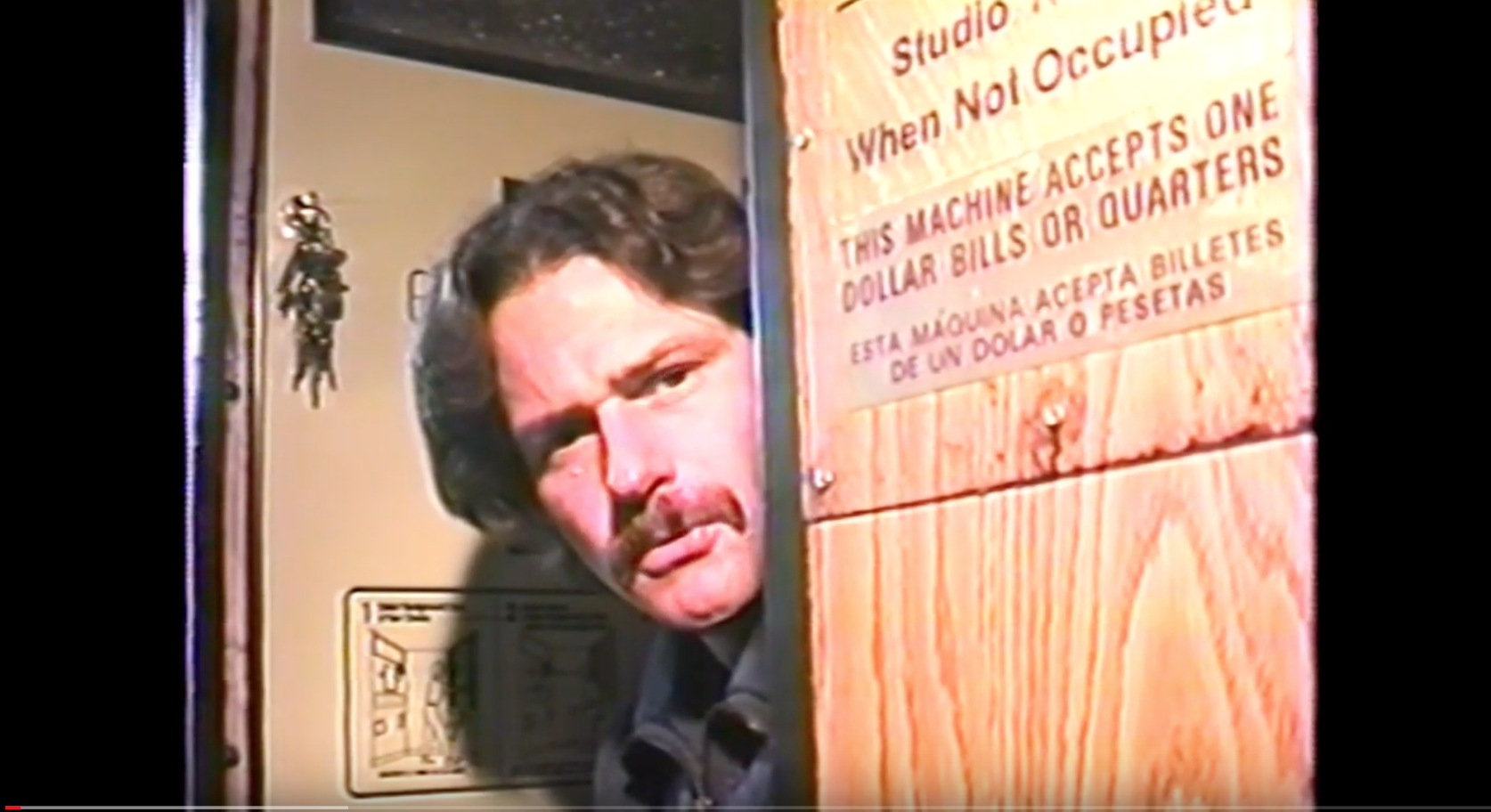

Inside however, hidden from view, is a carefully orchestrated system of electromechanical parts, gears, solenoids, relays, and switches all working in a perfect symphony.

On receiving payment, the mechanical camera inside the booth kicks into gear pulling a strip of paper from a large roll enclosed in a light-tight chamber. This strip of negative-to-positive silver gelatin photographic paper is placed in front of a prism that properly orients the image. A focal plane shutter turns as the paper moves across each flash.

When the photography process is complete, a spider assembly on top of a transmission flips out an arm. The arm takes the paper strip and moves it through a merry-go-round of tanks, dipping and dunking it in water baths, developer, bleach, clearing agent, and finally toner. Once it has been submerged in each tank, the arm drops the finished strip into a delivery unit outside of the booth where it is collected by the customer.

With so many moving parts, errors and mistakes are common, but we believe that it’s these tiny imperfections – blurred patches, discolourations and areas of over exposure – that bring an inimitable beauty to the photobooth images.